CARBON VANES & BLADES MAINTENANCE TIPS

HARDVANES Extended Technical Guide. 30 Critical intervention points to ensure absolute performance of your carbon vanes.

Slot Cleaning

It is imperative to eliminate absolutely every trace of carbon vane dust and particles from the rotor slots. Use powerful, dry compressed air.

Inlet Filters

Do not clean filters; replace them. A saturated filter causes a pressure drop (Delta P) that forces the pump to overwork, drastically raising internal temperature.

Bevel Orientation

Critical Point: The higher part of the blade bevel must always face the direction of rotor rotation. Mounting the vanes backwards is fatal.

ZERO Lubricants

In dry-running pumps, the use of grease or oil is prohibited. Carbon dust mixes with these agents creating an abrasive paste that will seize the vanes.

Rotor Inspection

Examine rotor slots under powerful light. Look for "washboarding". If present, the new carbon vane will vibrate and eventually stick or break.

Temp. Control

Monitor exhaust temperature. It should not exceed 120-130°C. Higher temperatures indicate excessive friction on the blades.

Shaft Bearings

Check radial and axial clearance. If there is play, the rotor loses its center and will strike the cylinder ("chattering"), pulverizing the carbon vanes.

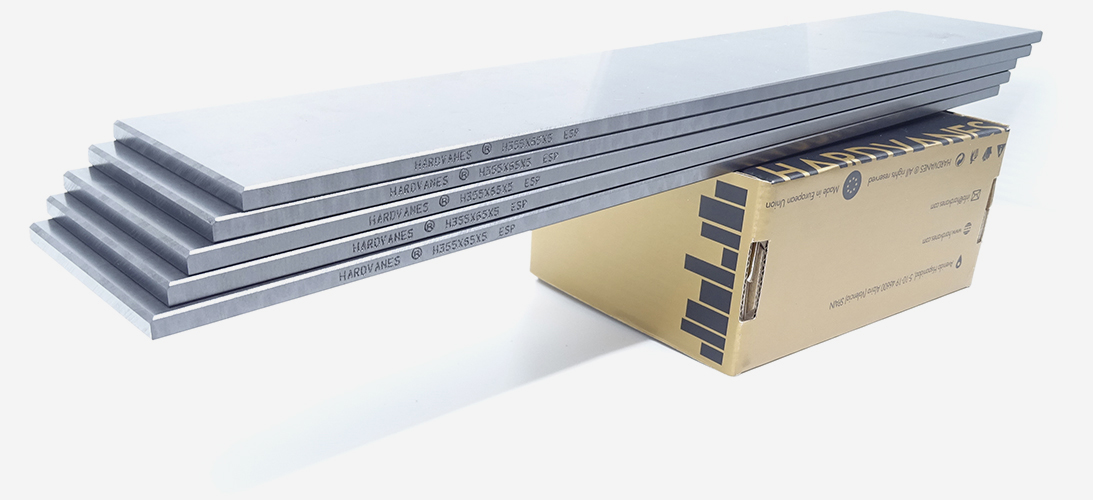

Dimension Check

Measure the height of the old blades and compare with the minimum specification to determine if replacement is due to wear or premature breakage.

Cylinder Condition

Run your finger along the stator interior. It must be mirror-smooth. If you feel grooves, the surface acts like sandpaper against new carbon vanes.

Motor Coupling

Inspect the elastic transmission elements (spiders). A worn coupling transmits shock loads and torsional vibrations directly to the rotor vanes.

Regulating Valve

Verify the vacuum relief valve setting. If improperly adjusted, the pump may operate outside its design curve, leading to severe overheating.

Exhaust Filters

Ensure they are not saturated. High exhaust backpressure restricts airflow and causes the motor to draw excessive amperage.

Side Clearance

Insert the new carbon blade into the clean slot. It should drop by its own weight. If force is needed, the vane will seize when hot.

Cover Gaskets

Never reuse damaged gaskets. A vacuum leak in the cover alters internal airflow and cooling efficiency. Always use new gaskets.

External Radiator

Blow compressed air through the external cooler (counter-flow). Accumulated dust acts as a thermal blanket, preventing heat dissipation.

Complete Sets

Unbreakable rule: NEVER mix new carbon vanes with used ones. Height differences will unbalance the rotor, causing destructive vibration.

Room Ventilation

If the technical room ambient temperature exceeds 40°C, the pump cannot cool properly. Consider installing forced extraction.

Rotor Burrs

If small nicks are detected at the slot entries, use very fine sandpaper. A sharp edge acts like a guillotine on the new blade.

LOTO Safety

Physically disconnect power and lock the switch before opening the pump. Accidental startup can cause severe amputation.

Non-Return Valve

-

The Issue: Upon shutdown, negative pressure causes backflow that reverses rotor rotation and damages the carbon blades.

-

The Solution: It is essential to install a non-return (check) valve or verify its spring closes correctly.

Consumption (Amps)

Use a clamp meter. Consistent high amperage indicates something is braking the rotor: tight vanes, clogged filters, or seized bearings.

End Plate Wear

Inspect the side covers. If the vane has "dug" a deep groove, gas will leak past the rotor. The plate must be ground or resurfaced.

Safe Storage

Carbon vanes are hygroscopic. Keep them in sealed bags until assembly. A blade swollen by humidity will jam in the slot.

Solvent Usage

Use fast-evaporating, residue-free cleaners. Any liquid remaining inside will form a paste with the carbon dust.

Rotation Direction

If the motor was disconnected, confirm rotation with a quick "jog" start. Spinning in reverse will destroy a new set of carbon blades.

Initial Break-in

Let the pump run for 20 mins in "free running" mode (open intake). This seats the vanes in the stator without maximum pressure load.

Piping Stress

Ensure pipes do not exert force on the pump. This deforms the housing, reducing tolerances and causing rotor seizure.

Grease Points

Only if greasable bearings are present, apply the exact amount. Excess grease is as damaging as a lack thereof due to viscous friction.

Maintenance Log

Record hours and dates. Keeping a log allows you to predict the real service life of the carbon vanes and schedule the next change.

Failure Analysis

If a catastrophic failure occurred, DO NOT install new blades until the root cause is found. Otherwise, the new set will break again.

HARDVANES ESPAÑA

Distribuidor Oficial en España

Supplyvac International S.L

AV EUROPA 87 Nº 2º 1ª

08850 GAVÀ - BARCELONA - SPAIN

NIF: B16931990

💬 Contacta por WhatsApp:

+34 685 090 732Tiendas Oficiales Hardvanes

🚚 Envíos Nacionales: GLS Logistics

✈️ Worldwide Delivery: DHL Express Priority

HARDVANES MÉXICO

Distribuidor Oficial en México

Hardvanes México

Avda Calzada de los Laureles 1274

Colonia Ciudad Granja

CP 45010,

Zapopan, Jalisco

México

RFC: GOHM790521MP9

💬 Contacta por WhatsApp:

+52 334 513 9797Tiendas Oficiales Hardvanes México

🚚 Envíos Nacionales: DHL Express

🇺🇸 Deliver to USA: DHL Express / FedEx

✈️ Worldwide Delivery: DHL Express Priority

HARDVANES PERÚ

Distribuidor Oficial en Perú

Vacuum Import S.A.C.

C. Las Capironas 395

Chorrillos 15064 – Lima – Perú

💬 Contacta por WhatsApp:

Tienda Oficial Hardvanes Perú

🚚 Envíos urgentes a todo Perú

HARDVANES CHILE

Distribuidor Oficial en Chile

Soluciones Biotecnológicas Las Mercedes

Camino Uno, Parcela 26

Batuco – Lampa, Santiago/Chile

Telf.: +56 9 3269 8859

Mail: contacto@sobitec.com

💬 Contacta por WhatsApp:

Tienda Oficial Hardvanes Chile

🚚 Envíos Nacionales: Starken / Chilexpress

✈️ Worldwide Delivery: DHL Express Priority

HARDVANES Česká Republika

Distributor České Republiky

LERISON s.r.o.

Novoměstská 1965/2

621 00 Brno-Řečkovice a Mokrá Hora

Česká republika

Oficiální obchod Hardvanes Česká republika

🚚 Expedice urgentně

HARDVANES TUNESIE

Distributeur Officiel en Tunisie

RD VERGES SARL

Résidence Le Palace, Bloc B, 1er étage, Bureau B 1-5

Centre Urbain Nord, 1082 Tunis

Tunisie

Site Officiel Hardvanes Tunisie

🚚 Livraison rapide à travers la Tunisie

HARDVANES ALGERIÉ

Distributeur Officiel en Algérie

RD VERGES SARL

Résidence Le Palace, Bloc B, 1er étage, Bureau B 1-5

Centre Urbain Nord, 1082 Tunis

Algérie

Site Officiel Hardvanes Algérie

🚚 Livraison rapide à travers l’Algérie

International Shipping with DHL Express

We provide fast and secure international deliveries via DHL Express. Trust us to ship your graphite vanes for vacuum pumps worldwide efficiently and reliably, ensuring your products arrive safely and on time.